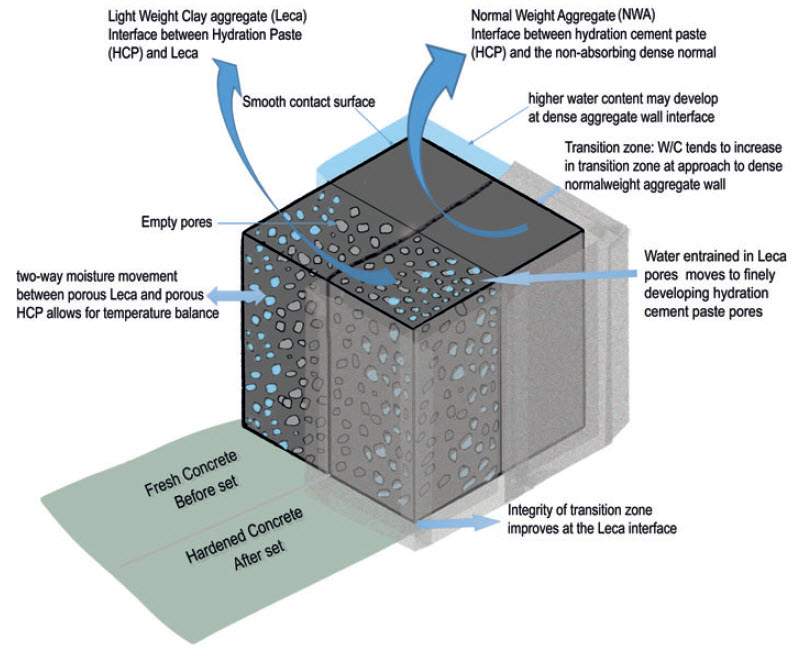

Difference between internal cured concrete and normal cured concrete

Advantages:

With an emphasis on durability, and with the trend to high performance concrete, internal curing is needed to reduce both autogenous shrinkage and cracking. The internal curing process magically happens within an ordinary concrete mixture. Since concrete cracking is most often the result of overt shrinkage, the life of concrete can be severely reduced as early age cracks grow in size.

Cracks weaken the concrete by exposing its insides to many deleterious things from its in situ environment. Over time, concrete cracks become exacerbated as small cracks grow into larger cracks.

Time dependent improvement in the quality of concrete containing pre-wet lightweight aggregate is greater than normal weight aggregate.

According to specifications, the amount of lightweight aggregate needed is based on the absorption and desorption of the aggregate being used. Most practical concrete applications, seven pounds of Internal Curing water per 100 pounds of cementitious material, provide an appropriate value for the amount of Internal Curing moisture needed. However, the amount of Internal Curing water may be increased to accommodate evaporation or to satisfy the higher water demand in mixtures with supplemental cementitious materials.