Modern Era Sustainable Buildings Using LECA Precast Elements Approach

“Green” or “sustainable” buildings contains key resources such as energy, water, materials more efficiently than buildings that are just built normally.

LEED (Leadership in Energy and Environmental Design) was designed and built using strategies aimed at improving performances such as energy savings, water efficiency, CO2 emissions reduction, improved indoor environmental quality, and stewardship of resources and sensitivity to their impacts.

The system is categorized into five basic areas: Sustainable Sites, Water Efficiency, Energy and Atmosphere, Materials and Resources, and Indoor Environmental Quality.

In the Building industry, there are different types of materials which help LEED system to grow and expand. LECA (Light Expanded Clay Aggregate) is one of this material which improves LEED performance by its main advantages such as Lightness, Thermal Insulation, Sound Insulation, fire resistance and limited water absorption.

LECA (Light Expanded Clay Aggregate) is a porous ceramic product with a uniform pore structure of fine, closed cells and with a densely sintered, firm external skin. It is manufactured in Rotary kilns from raw materials containing clay minerals, between 1100 °C and 1200 °C, resulting in a significant increase in volume due to expansion. The LECA pebbles internal cellular structure with thousands of air-filled cavities gives Thermal and Sound insulation properties.

LECA Production system operates an environmental management system that complies with voluntary international Standard ISO 14001:2004 and Health and Safety Management Best Practice that meets British Standard BS OHAS 18001.LECA manufacturing process respects the environment and total absence of harmful emissions ( even in the presence of fire ) make it ideal for sustainable construction. LECA is an expanded ceramic and ceramic which is not hazardous to health. Due to its Ceramic base, it is recyclable material and it lasts longer. In addition, LECA plant uses a lot of recycled food industry waste as fuel which helps to protect an environment and limit the carbon footprint of material.

Products made from LECA Aggregates are Lightweight Precast Elements, Lightweight Concrete and Lightweight and Insulating Grout.

Lightweight Concrete: Structural or non-structural lightweight concrete can be defined as a concrete with closed or open structure contains both ordinary aggregate and LECA aggregate. In addition to the weight saving, lightweight concrete has substantially better fire-resistant qualities, significantly lower heat transmission, remarkable moisture resistance and more durability than normal weight concrete.

Insulating Grout: LECA Mortar is a type of premix of Lightweight concrete which can be used for several applications such as roof insulation, cover steel member to protect against fire and corrosion and it applies for block work to decrease more weight per square meter and increase the thermal/sound insulation.

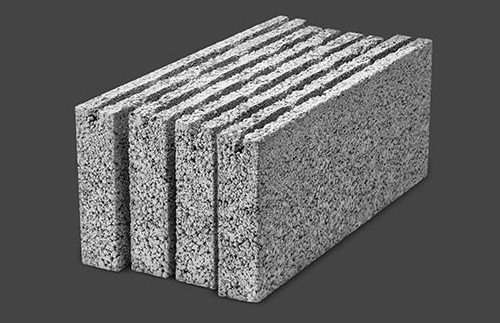

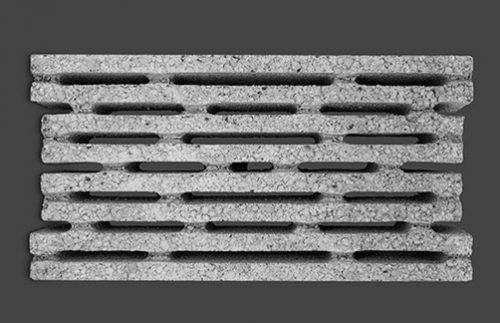

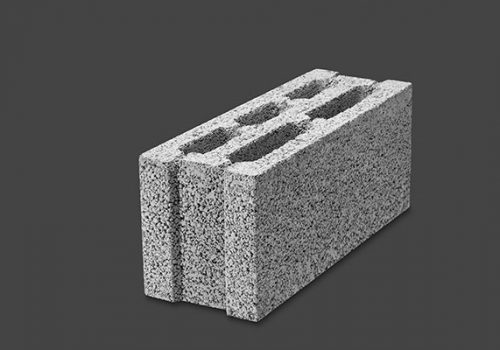

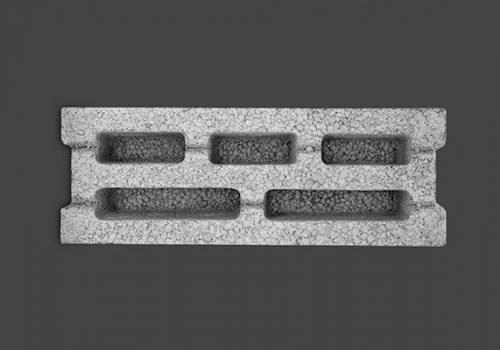

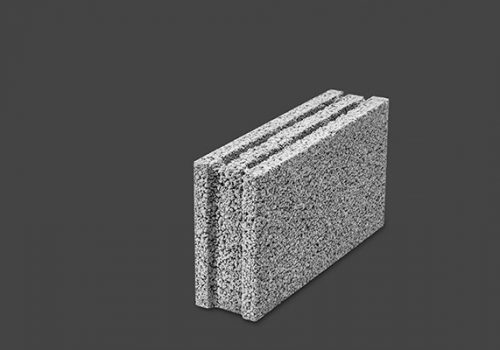

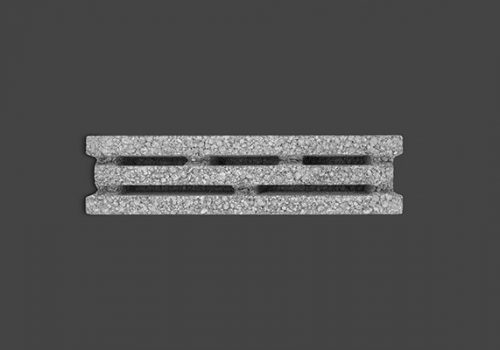

Lightweight Precast Elements and Masonry Units: LECA is the raw material for many prefabricated components. LECA blocks, prefabricated panels, lightweight bricks artificial stones floor tiles wall tiles and pavement are well-known products which have advantages of lightness, moisture resistance, fire resistance, sound insulation and thermal insulation. Leca Building blocks are produced by mixing LECA with cement, sand and water. The lightweight blocks are cast in normal block making machines that compact and vibrate the concrete in one single operation. Leca block is ideal for all types of exterior and interior walls and suitable for any physical operation such as cutting, nailing, transfixing or screwing also ridge extending to make a proper route for wire, pipe and other installing components without any cracking on the surface of the material. There are different types of LECA Lightweight blocks with different shape and dimensions.

LECA GREEN BLOCK